It’s 2016, and EPA Tier 4 Final is firmly in the rearview mirror. So we can all relax, breathe a big sigh of relief and never worry about increasing emissions standards ever again. Right?

I can hear your “yeah, right” from here.

Bruce Kaplan, Product Development Manager, Thermal Structures, Inc.

Bruce Kaplan, Product Development Manager, Thermal Structures, Inc.

Benjamin Franklin once said, “In this world, nothing can be certain except death and taxes.” If the founding father were alive today, he might add “increasingly strict emissions standards” to the list.

Of course, the EPA hasn’t announced any plans for a Tier 5. But we can make an educated guess. Europe already has announced Stage V, and some engine manufacturers have already admitted they’re expecting an EPA-mandated Stage 5 sometime around 2019.

No one knows for sure exactly what regulations the EPA or CARB (California Air Resources Board) or some other regulatory agency will be handing down a few years from now, but the smart money is on a general trend toward stricter regulations.

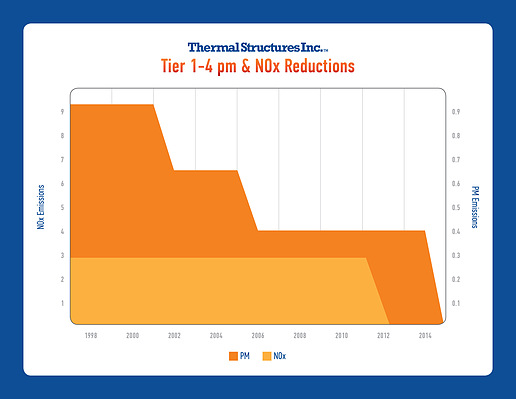

Under Tier 4 Final, particulate matter (PM) and nitrogen oxides (NOx) emissions have fallen pretty close to zero, but it’s still possible they could be reduced further. Europe’s Stage V pushes allowable PM emissions down even more, and some have speculated that future regulations could take aim at CO2 or other emission byproducts.

From the implementation of Tiers 1-4, we’ve also learned that meeting increasingly stringent emissions requirements goes hand-in-hand with the creation of increased heat. Sometimes that heat is an essential part of the process, like with diesel particulate filter (DPF) regeneration. Other times it’s simply a byproduct.

Metal foil encapsulated thermal insulation on an ATV (all-terrain vehicle) exhaust system reduces touch temperature for safety and shielding of nearby rubber components.

Metal foil encapsulated thermal insulation on an ATV (all-terrain vehicle) exhaust system reduces touch temperature for safety and shielding of nearby rubber components.

Whatever the cause of the heat, we know that the thermal insulation that was perfectly adequate for a pre-1996 engine would be completely inadequate for a Tier 4 Final engine being built today. It’s safe to assume that, in the future, we’ll see even more heat.

So how will we manage the heat of future engines? Will we need to invent entirely new technologies? Forge brave new frontiers? Maybe. But more than likely, we’ll be doing more adapting than inventing.

During the implementation of Tiers 1-4, companies like Thermal Structures faced unprecedented challenges in helping vehicle and engine manufacturers meet the insulation demands of hotter-than-ever engines. Fortunately for diversified companies like ours, we didn’t have to look too far for those solutions.

For decades, we’ve been building extremely high-performance insulation for military and commercial aircraft. When you’re flying at 36,000 ft and burning Jet A at around 1650°F (900°C), high-performance thermal insulation is a standard requirement.

When we were meeting the challenges of Tiers 1-4, we were able to draw on our experience with aerospace thermal insulation, and adapt those solutions for off-highway applications. In many cases, that meant developing solutions that drew on aerospace technology to block more heat in less volume, while reducing the (often very high) cost of aerospace insulation solutions by removing features that weren’t necessary on the ground.

The aerospace industry traditionally pays a premium for performance, weight and even aesthetics. So while we were able to draw on our aerospace experience, directly applying aerospace solutions to the off-highway market would have been cost-prohibitive, and less than ideal.

Take, for example, foil insulation in an airliner’s engine. With this application, a very-thin lightweight foil insulation skin is often ideal. But in an off-highway market that now needed similar thermal conductivity to the aerospace market, the very-thin lightweight foil skin that was perfect for aerospace didn’t do too well in rough-and-tumble off-highway applications. So, we adapted our aerospace designs to work with heavier gauges of foil insulation, and sometimes even sheet metal to deliver extremely low thermal conductivity along with a more robust design.

The other big change was in the insulation material itself. Before the advent of Tiers 1-4, the only extremely-low conductivity insulation material was aerospace-grade. I’m sure you’ve heard the adage that adding the term “Aerospace-grade” to just about anything implies adding a zero to its price tag, and the off-highway market experienced a bit of sticker shock at the cost of pure aerospace-grade insulation materials.

From the implementation of Tiers 1-4, the industry has learned that meeting increasingly stringent emissions requirements goes hand-in-hand with the creation of increased heat.

From the implementation of Tiers 1-4, the industry has learned that meeting increasingly stringent emissions requirements goes hand-in-hand with the creation of increased heat.

As we got further into the EPA’s mandated engine upgrades, insulation material manufacturers began to develop “industrial grade” insulation. These materials met the demand for insulation materials that delivered equivalent thermal conductivity, without the “aerospace-grade” costs. In most cases, this was a matter of using a less-costly material, but with a similar design.

Today, many thermal insulation innovations that were first developed for aerospace applications have been adapted for off-highway engines and equipment. The good news for tomorrow’s emission regulations, whatever they might be, is that demand from the industrial market is driving down the cost of high-performance thermal insulation.

Source: sae.org