Everyone with experience on the track will attest to the value of a sport tire. Increased cornering speeds, more feel, better steering response, immense braking ability and more are all accessible with a proper set of rubber, but rarely do people give thought to what makes these tires work, and how to best use them. To excel on the race track, a comprehensive understanding of these cylindrical cuts of rubber is a must, since whatever colossal powerplant or sophisticated chassis is used, it’s only as good as the tires which support it.

However, a competition tire is subject to a number of different demands depending on the context in which it’s used. It has to be friendly on the limit, resilient, reliable and stable under loading. Factor in the need that a sporting tire has to disperse some water and be fairly accommodating, and producing something that is universally appealing becomes quite a tall order. Predictably then, it took some time to find an ideal compromise.

Developing Radial Grip Through the Decades

French tire giant Michelin introduced the radial tire two years after World War II with the Michelin X. Twenty years later, B.F. Goodrich developed the radial tire to overcome the current-favorite, bias-ply tire, which was more comfortable but lacked the sort of rigidity and longevity that Goodrich’s radial offered. A radial tire’s carcass plies are arranged in a directional pattern, which prevents deformation, and thus improves fuel economy.

In the racing world, the bias-ply was still the norm, thanks largely to its lightweight construction. However, the radial began to appeal to the enthusiasts for a number of reasons related to racing. It offered greater stability, especially at high speed. However, what kept the radial from catching on in ‘fifties road cars was their increased cost and their harsher ride quality. Remember, the automobiles from the fifties and sixties were largely about creature comforts — if the Cadillac wasn’t sumptuous to seat eight comfortably and give ample room for the drive-through malts, it wasn’t selling.

The overlapping sheets of a bias-ply tire are visible here. Unfortunately, the crown and the sidewalls of the tire move in unison, which generates heat and limits the effectiveness of the contact patch. Photo credit: Michelin

The overlapping sheets of a bias-ply tire are visible here. Unfortunately, the crown and the sidewalls of the tire move in unison, which generates heat and limits the effectiveness of the contact patch. Photo credit: Michelin

However, in the late 1960s, the slick tire was introduced to the racing world. Teams were experimenting more and more with chassis design and grip, so they looked to increase the size of the contact patch by eliminating tread altogether. While treaded tires were still used for rain racing, the gains found in slicks pushed forward tire development in motorsports. Now, the cornering potential of these cars were rapidly advancing, especially since this period coincided with the introduction of wings.

Racing tires, specifically those used in Formula 1, rely on a different sort of construction to keep the weight low. In the 1970s, F1’s tire suppliers still used bias-ply tires, which would flex quite easily, but were light. Intent on pushing the radial tire, Michelin introduced it to Grand Prix racing in 1977, feeling the correlation between their racing tires and road tires would be obvious to a discerning public. Besides of marketing reasons, however, the radial tire’s numerous performance advantages were what made it appealing to racers.

Michelin’s radial tire improved fuel consumption with a stiffer composition, which suited the gas-guzzling turbo F1 cars of the seventies and eighties well.

Michelin’s radial tire improved fuel consumption with a stiffer composition, which suited the gas-guzzling turbo F1 cars of the seventies and eighties well.

Radials had been developed somewhat by that point, and were beginning to steal the spotlight. The advantages bias-ply tires held then were becoming outweighed by the fact that their lack of radial plies underneath the tread made them more sensitive to pressure changes. Crucially, the layered construction of a radial tire offered greater rigidity, less sidewall flex, and therefore a more consistent contact patch. From then on, the radial was the norm, and over the decades, the modern performance tire has caught up to the standards of the racing tire.

Kenneth Payne, technical director for Michelin and BF Goodrich for the past 28 years, notes, “What was a race tire performance level 20 years ago is now an ultra high street performance tire.” This comes largely in thanks to changing materials: Payne attributes the improvement of tire performance to “carbon black fillers to silica compounds to evolutions of elastomers.” However, it took some time for that performance to be translated into a streetable tire along with all the other demands everyday driving places on it.

Constructing a Sport Tire for the Enthusiast

Having a clear connection between production tires and racing tires improves tech and sells rubber. Photo credit: Bob Chapman, Autosport Image

Having a clear connection between production tires and racing tires improves tech and sells rubber. Photo credit: Bob Chapman, Autosport Image

The construction of a road-ready, competition tire isn’t easy. This is because one that works well on both the street and the track is quite different than the tire used in top-tier motorsports, despite having similar purposes, seemingly. For these sorts of tires, there are an interesting mixture of requirements which they must adhere to. First and foremost, the tires have to be usable on the street and address all the demands that involves.

In marketing a performance tire to the public, a few considerations have to be made. First of all, these tires must be usable in a variety of circumstances, and they must be communicative on the limit. While sport tires are designed primarily for speed, they are not a slick, and are fitted with the necessary two grooves to receive a DOT rating. This style of construction allows for some, albeit limited, ability for water dispersion.

Toyo’s R888 works wonders in the dry but its minimal tread limits its ability to dissipate water.

Toyo’s R888 works wonders in the dry but its minimal tread limits its ability to dissipate water.

One concept often overlooked when it comes to tire performance is the temperature range in which they work well. Drew Dayton, Product Manager at Toyo Tires, notes, “A traditional street tire doesn’t need a significant amount of heat buildup the way an R-compound does.”

In the case of R-compound tires, they need a considerable amount of heat before they work. Dayton mentions, “The operating range for our R-compound tires is 160°F to 220°F. Below 160°F, the tread compound will not be generating its maximum levels of traction, while above 220°F, the traction begins to degrade and continued temperature increases will risk blistering of the tread compound.” This focused tire is primarily designed to be very quick on dry and preferably warm days, and aren’t advocated for wet weather use, because while they function in the wet, their focused nature limits their effectiveness on sodden roads and in standing water.

The tread present on road tires flushes water away from the surface of the tire, but also helps manage the specific loads the tire is subjected to. For this reason, tread flex is a major separating factor between focused sport tires and the kind of rubber that a station wagon typically wears. Kenneth Payne notes, “For road racing, we really focus on stiffness and stability. At the opposite extreme, for winter tires, we want a lot of biting edges and block mobility.”

Crucially, an R-compound needs to be more durable than an all-out racing slick. After all, many professional racing teams will run through several sets of expensive slicks in the course of a few hours, which is far too expensive for the enthusiast. While being driven hard in a reasonably warm environment, this tire will typically last longer than something softer which tends to offer more grip but disintegrates faster, which has made it appealing to certain categories of grassroots motorsports and endurance racing, where tire conservation and modest budgets are major concerns.

Durability and consistent performance means the off-the-shelf Toyo R888 is used widely in series like Spec Miata. Photo credit: Mark Weber, SCCA.

Sidewalls and Stiffness

Durability and consistent performance means the off-the-shelf Toyo R888 is used widely in series like Spec Miata. Photo credit: Mark Weber, SCCA.

Sidewalls and Stiffness

Another consideration which must be made to the construction of a sport tire is the rigidity of the sidewall, which is both good and bad. Since the amount of roll and chassis flex has been controlled better with modern cars, they can better exploit the added stiffness from rigid sidewalls. “In general, a stiffer sidewall will result in less deflection, resulting in better response to inputs,” Dayton observes.

However, that can come at a price. Generally speaking, a little bit of flex in the sidewall is a way of making the transition from gripping to slipping more progressive by offering more warning and, effectively, widening the traction window. Keep in mind the skills of an average enthusiastic driver versus those of a professional racing driver, and the way in which tires are constructed makes more sense. “The tools we use to develop some of our wet weather tires for competition are used to develop Pilot Sport tires for the street,” remarks Payne.

With that sidewall beginning to flex as the car rolls, the driver has a sense that they’re nearing the edge of adhesion. Again, with the added amount of cornering speed these sorts of tires offer, that added speed will only require some quicker steering input when the tires do break away, so that feel of an impending slide helps keep drivers out of the walls. Not every enthusiast has Senna-like reactions.

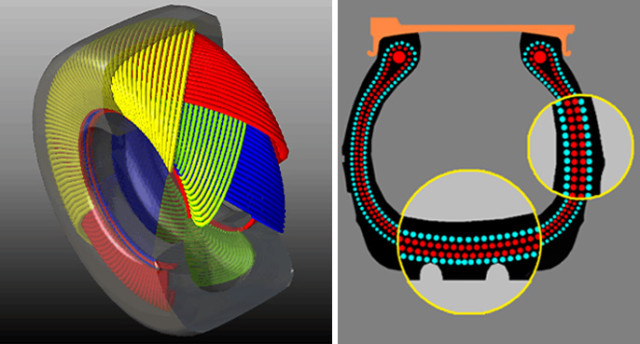

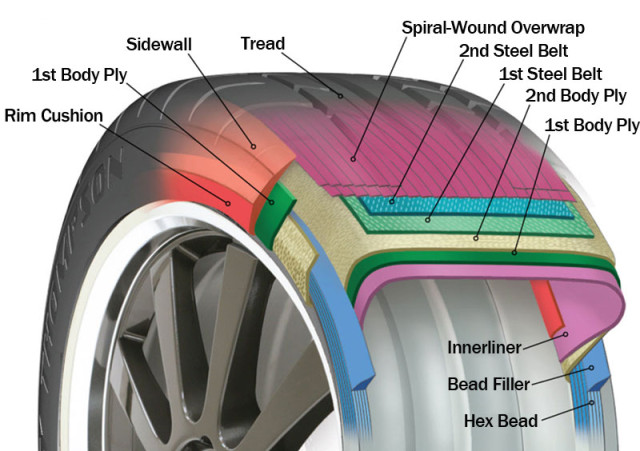

With this high-performance street radial, the plies are arranged radially from the center of the tire, which allows for crown movement independent of the sidewall. Photo credit: JEGS

With this high-performance street radial, the plies are arranged radially from the center of the tire, which allows for crown movement independent of the sidewall. Photo credit: JEGS

Additionally, “A tire also acts like a spring in suspension systems and has an effect on the overall wheel rate of the system,” says Dayton. While some might suggest altering the air pressure within the tire, it’s not a consistent means to control damping. This is because air pressure within the tire will inevitably change with heat, and often over-inflated tires begin to skip across the road.

Finding the Most Performance

Any savvy driver knows that racing is resource management. Knowing how to get the most from a set of tires is then a very important skill, even if all that’s in store is a series of fast laps on an informal track day. There are lots of old old timers who will wax lyrically about the benefits of smoothness, but that’s largely because in the older days with bias-ply tires, those that could really soften their inputs enjoyed a noticeable benefit. Nowadays, thanks to better tires, those benefits are harder to witness.

However, physics haven’t changed in the past fifty years and the same rules apply. A smooth application of the steering, throttle, and brakes have drastic effects on the heat generated by the tire, and therefore it’s important to learn how not to over-extend a set. Learning how to get the most of one’s tires begins with the warming procedure.

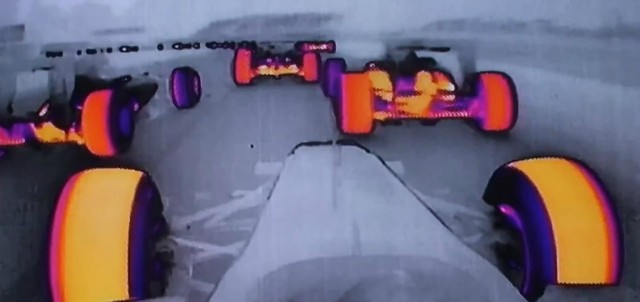

Thermal imaging helps us understand how racing tires generate and transfer heat throughout the different phases of cornering.

Thermal imaging helps us understand how racing tires generate and transfer heat throughout the different phases of cornering.

The dramatic way tires are warmed scrubs the surface of the tire. That immediate input slides the tire over the surface of the road, and thus generates heat through friction. However, it’s also helpful to combine those dramatic inputs with some braking and throttle to stretch the tire with a combination of lateral and longitudinal loading, so the entire carcass is warmed, and not just the surface. Dragging the brake can warm the rim, which in turn warms the tire it contacts.

It’s for these reasons that once the tires are at their ideal operating temperature, the inputs should be applied progressively, so as not to overheat the tire, especially since sporting and racing tires tend to work well within a narrow temperature range. Jay Jones, instructor for the San Diego Region BMW Car Club of America, notes that “hacking and sawing on the steering wheel heats the tires because you’re deflecting the walls and adding scrub.” Smooth, progressive inputs help keep the tires from getting too hot and blistering.

It’s also for this reason that some racers begin their race strongly, sail off into the lead temporarily only to begin falling back on a set of blistered tires. It’s integral to any driver’s success to learn how to best manage their rubber; when to push and when to conserve. This comes down to feel and experience.

While the shortest line might involve hopping curbs, bouncing the tire up and down increases tire temps and is not great for pace over the entire race.

While the shortest line might involve hopping curbs, bouncing the tire up and down increases tire temps and is not great for pace over the entire race.

Knowing how to drive a set of tires takes restraint and experience. As the tire develops heat and begins to grip, it’s sometimes tempting to push the car into a slide, scrubbing speed ever so slightly. To the intermediate driver, this often feels good because they know all their effort had been put into cornering, but this sort of added energy only increases the rate of tire degradation, and little if no time is gained. To sense wasted energy is something that can take years to learn.

This sensitivity comes in useful in the rain also. Knowing the depth of the tire’s tread and its response to oily, slick, or damp sections of asphalt is imperative, but the real concern is heat. In wet conditions, the tire is threatened by not getting up to operating temperature. Using the dryer and wetter parts of the circuit to warm and cool the tires, respectively, is a skill that only the best master.

While some might assume otherwise, it’s always the tires that determines performance. A solid understanding of how they work that determines success over the course of a season. During a qualifying session or a short race, the wilder driving styles can, depending on the circumstances, prevail. But to win consistently, a driver needs to treat their tires with a degree of understanding and consideration that many veterans of marriage counseling would be jealous to have.

Nguồn: turnology.com