By Michael Hunter, Global Technical Director, APTech Group, Inc.

Introduction / History of Solid Water Treatment

Cooling towers and chillers operate by running water through them in order to cool buildings or for “process” purposes in industrial settings. Since water comes into contact with the metal in this equipment, as well as heat exchangers, there is the ongoing opportunity for scale build up and corrosion depending on the water quality in the systems.

During the last 40 years of the 20th century, the standard method for treating the water that runs through cooling towers and systems was to use blended liquid water treatment chemicals. Generally these liquid products were delivered by tanker truck or common carrier trucks. The liquid chemicals were fed into the cooling systems by a variety of pumps to protect the systems from potential corrosion, scale build up, and microbiological fouling.

This method of treating cooling systems was generally effective when managed correctly. However, liquid water treatment chemicals had a variety of issues and concerns associated with their application. Many of these products were (and are) labeled as corrosive owing to the pH (acidic or caustic) of the ingredients. Potential issues with liquid products include the following:

|

Issue

|

Result |

| Potential for spills during shipment |

Environmental hazard, potential for injury reduced or eliminated |

| Shipping costs |

Water is more than 80% of the product in liquid formulations; requires truck shipping, meaning increased expense |

| Handling liquid containers |

Time consuming, potential for injury |

| Container storage |

Space and containment requirements, eye wash stations |

| Dealing with empty containers |

Triple-rinsing required, time consuming, wastes water, storage of empty containers, plastic disposal (ie: land fill) |

Around the most recent “turn of the century”, in answer to the challenges associated with liquid chemicals, solid-form chemical products for cooling towers (as well as boilers and closed loop systems) , along with dispensing systems to reconstitute the solid products back to liquid form on-site, began to be developed and introduced to the market by multiple companies.

An installation of the AP Tech solid cleaner. An installation of the AP Tech solid cleaner.

|

How Solid Chemical Water Treatment Products Work

Manufacturing Process

Most solid-form water treatment products are produced by combining raw materials of proven chemical combinations producing a finished product which is best described as a water soluble wax-like, hard putty. A range of cooling system water treatment chemical products is available in solid form from a number of manufacturers, ranging from scale and corrosion inhibitors to specialty products and biocides. Additionally, there are a couple of solid-form products available for smaller applications that require less control. These include tablets of inhibitors covered with a coating and housed in a membrane for system delivery, as well as inhibitors and dispersant package compressed into a 2” puck.

Solid Chemistry Product Forms

Many solid product formulations, similar to their liquid counterparts, are available in the market. These solid products are utilized by professional water treatment personnel when treating and maintaining cooling systems for their customers. Product packaging configurations include:

- Recyclable Plastic Bottles -- 1 gallon in size, weighing 11 pounds per bottle, packaged 4 bottles to a case

- Discs – 6” in diameter by 3” tall, weighing 5 pounds each, packaged in disposable plastic

- Sticks – 5” long, 2” inch wide, generally .8 pounds each, packaged in PVA materials which dissolve during use

- Encapsulated Tablets – Small (approximately 1/2” in diameter) of scale and corrosion inhibitors. 10 – 2.5 pounds of product in mesh bags per case

- Pucks – 2” in diameter, 6 to a package with a hook to hang in the system

Photo 1: Examples of solid chemical product forms-discs, bottles, sticks, box

Each of these solid product forms is designed for individual, specific applications. The bottles are the most commonly used solid product form. The water treater removes the cap and places the bottle in the dissolving unit and changes the bottle when empty. Empty bottles can be rinsed and recycled.

The discs are most useful for larger systems or when the water treater is unable to visit the customer site frequently enough to change bottles. Up to 4 discs (20 pounds) may be stacked in a dissolving unit at one time – equivalent to 30 of conventional liquid inhibitor. For larger systems, bespoke dissolving equipment is available.

Encapsulated, timed release products use a coating and membrane system to control the release of the scale and corrosion inhibitors. Designed for use in smaller cooling towers (500 tons or less) that don’t require controllers or pumps, the inhibitors are released over a 30 day period.

Pucks or tablets are a 2 inch diameter “sandwich” of scale and corrosion inhibitors with a dispersant in the center. The puck has an embedded plastic hook to enable hanging the product in the tower wherever water flows over it. Pucks are for very small (under 25 tons) cooling towers and last about 30 days.

Solid-Form Product Dissolving Alternatives

Since solid water treatment products are shipped in concentrated form, the chemicals are dissolved on site at the point of application using make-up or city water and dissolving boards or feeder units (or in the case of Sticks or Pucks; directly in an open portion of the system). For Bottle or Disc products, the dissolving units are available in a number of configurations, with or without a reservoir, and electrically powered or gravimetric/magnetic. The unit is attached to a wall and connected to an incoming city water line. An outgoing line is connected from the dissolving unit to existing chemical feed equipment (typically a pump or educator) and if electrically powered, plugged into a 110 volt outlet. (For safety, the voltage is reduced to 24 volts.)

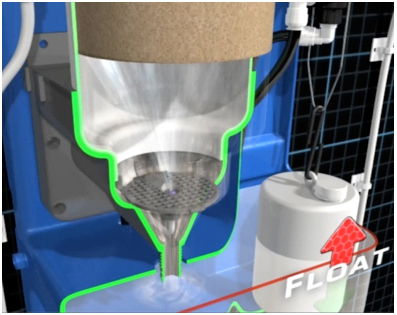

The plastic bottle or disc is then positioned in the receiving well of the dissolving board (upside down in the case of the bottle). For units with reservoirs, as the water treatment system controller “calls” for chemicals, a solenoid valve opens and incoming water is sprayed through a specially configured and calibrated spray nozzle up into the bottle or onto the surface of the lowest positioned disc. This action dissolves a portion of the chemical and mixes it with the spray water in the reservoir. The reservoir empties as the chemical pump serves the now liquid product, into the cooling system to protect the system components. These activities continue based on the demands of the system and the settings in the controller.

Photo 2: Dissolving unit spray pattern with float functionality. Photo 2: Dissolving unit spray pattern with float functionality.

|

For the encapsulated solid products, the gray feeder units are mounted to the floor and attached to a wall or mounting frame. These units don’t require a chemical pump as chemical is dissolved whenever recirc water is flowing.

Photo 3: Dissolving units with reservoir for solid products, configured for use with bottles and discs, left and center image. Feeder units for encapsulated products, right image.

|

Building facility management professionals or water treatment specialists monitor the system and change bottles or add discs as necessary to enable ongoing chemical feeding. In the case of encapsulated products, they are replaced at 30 day intervals. Periodic system monitoring by way of traditional water treatment testing procedures, such as Molybdate, Phosphonate, etc., assists in keeping the system treatment at correct and necessary levels for proper system protection against corrosion, scale and biologic contamination.

Comparing Solids to Liquid Water Treatment Chemicals

Liquid and solid water treatment products have a number of common traits. They are both produced by blending chemical combinations that are historically proven to combat the issues that can shorten the useful lives of cooling towers and chillers. Different polymers and azoles are combined in both liquids and solids to deal specifically with water that is either scale forming or corrosive in nature and also to manage and control suspended matter that may be entrained in the system water. Both forms of chemistry are ultimately served into the systems they maintain via pumps or eductors and are regulated or managed by sophisticated computer-based Controllers.

Photo 4: Typical liquid chemical (left), solid bottle (center) and encapsulated (right) chemical installations. Photo 4: Typical liquid chemical (left), solid bottle (center) and encapsulated (right) chemical installations.

|

Monitoring of system chemistry for solid water treatment products is the same as for the liquid formulations currently available. Typical monitoring or testing methods for both forms include testing for levels for Molybdate, Phosophonate and Tolyltriazole in the cooling system water.

There are also a number of differences between these two forms of water treatment products. When initially manufactured or produced, most liquids have some amount of additional caustic in the products to maintain the other ingredients in solution. Since solid products are reconstituted to a liquid onsite in the reservoir of the dissolving board, at the time of delivery to the system, dangerous caustic is not required as an ingredient, unless it is necessary to treat a specific water condition. (The dissolved chemical in the reservoir is stable without any added caustic due to a relatively low concentration level.) Even with the addition of caustic, liquid products generally contain up to 80% or more of water in the products.

These two “ingredients” (added caustic and water) mean that shipping liquid water treatment chemicals in 55 gallon drums weighing 500 pounds each, is both costly and in many cases, dangerous. It also means that they must be shipped as “hazardous product”, since they include caustic. Solid products, on the other hand, weigh less than 50 pounds per case. Most solids, with the exception of biocides can be shipped by UPS or FedEx, meaning quicker delivery and lower shipping costs. Biocides, whether in solid or liquid form are considered hazardous, from a shipping perspective and must be shipped by common carrier (or by UPS if the shipper or the recipient has a “hazardous shipping contract”.)

Photo 5: A 55 gallon (500 lb) drum of liquid water treatment chemicals (left image) will consume 2.5 more gallons of diesel fuel per typical shipment than a 44 pound carton of four solid chemical recyclable bottles with same amount of active ingredients (middle image). Right image shows 25 pound box of encapsulated solid product. Photo 5: A 55 gallon (500 lb) drum of liquid water treatment chemicals (left image) will consume 2.5 more gallons of diesel fuel per typical shipment than a 44 pound carton of four solid chemical recyclable bottles with same amount of active ingredients (middle image). Right image shows 25 pound box of encapsulated solid product.

|

Solid water treatment chemicals have number of other advantages over their liquid counterparts. A case of product in “bottles” weighs 44 pounds. A case of 10 mesh bags of encapsulated product weighs 25 pounds. Both of these types of solid water treatment products are easily carried through customer buildings and stored in (often) small mechanical rooms. Additionally, since solids do not require caustic to be added to keep the product the product in solution, expensive containment areas or eye wash stations are not necessary.

Like liquid products, solid form chemicals are useful in a wide array of commercial applications ranging from commercial buildings to government facilities and light industrial applications. For very large applications such as cooling towers in large industrial applications, liquid products in totes may remain the most efficient treatment method. However, due to their increased sustainability traits, including reduced fuel used in shipping, reduced spill concerns, reduced potential for injury, reduce carbon footprint and the optimization of space utilization in mechanical rooms solids are especially attractive to facilities such as hospitals, universities, primary and secondary school systems and office buildings. Senior management of these kinds of organizations and facilities are increasingly placing an amplified emphasis on such considerations across their entire entities – not just in the facility management arena. Solid water treatment chemicals are becoming a common component in the overall sustainability game plan of these types of institutions. In fact, for these reasons, mechanical engineers are increasingly being asked to specify solid water treatment chemical configurations in new buildings or renovations.

The following example is emblematic of the sustainability benefits of solid water treatment chemicals: A Cooling Tower on a 20 story office building which produces 1,000 tons refrigeration requires this amount of annual liquid chemistry, in 55 gallon drums, to treat the water in this Cooling Tower:

- 12 barrels of scale/corrosion chemistry

- 4 barrels of micro biological chemistry

- 4 barrels of cleaners

In this example, the twenty 55 gallon barrels of liquid chemistry are shipped 600 miles to the office building via trucks using diesel fuel. Based on this data, utilizing solid form water treatment products to treat this 1,000 ton Cooling Tower instead of liquids would generate the following Carbon Dioxide (CO2) reductions (also known as Carbon Footprint savings):

| Transport fuel savings |

826 lbs of CO2 per year |

| Sodium Hydroxide (NaOH) savings |

1,776 lbs of CO2 per year |

| Plastic used reduced |

1,084 lbs of CO2 per year |

Total Savings

|

3,686 lbs of CO2 per year |

These savings are comparable to an individual leaving his/her car in the garage for 173 days and walking or taking public transportation (based on a vehicle that averages 10,000 miles / year @ 25mpg).

Performance of Solid Water Treatment Products

Solid water treatment products have generally been found to protect equipment as effectively as traditional liquid chemical products, when correctly implemented. In addition, results have shown that solids can help a facility become more sustainable, as these two case histories show. The first case study is a description of the benefits the new system provided – both technically and from a sustainability perspective for a very large shopping comfort cooling program. The second case study describes the results of a solids system implementation in a large government office building which had severe scaling problems.

Large Shopping Center

A very large shopping center had been using liquid water treatment for many years in its cooling system. The technical results had always been acceptable. In recent years, however, the management team of the shopping center had become more and more focused on environmental issues. The management team worked with the water treatment partner to add sustainability areas of interest to the traditional water treatment and maintenance objectives to form a comprehensive, multi-directional series of goals for the new program:

- Control of Corrosion

- Control of Deposits

- Control of Fouling

- Microbiological Control

- Net Loss of Water

- Rate and Cycles of Concentration

- Analytical Results

- Consumption of Chemicals

- Dosing Systems

|

- Control Systems and Monitoring

- Storage Space for Chemicals Containers

- Storage Space for Empty Containers

- Need to Build Containment Basins

- Occupational Safety

- Operating Facilities

- Environment

- Heat Exchange Efficiency

- Specific Energy Consumption

|

In addition to establishing these categories of objectives, the facility management team developed a simple 5-star rating system to translate the technical water treatment data to a form more easily understood by the shopping center upper management. Not all of these categories of data are completely impacted by the solid-form water treatment. But they are included to show the degree to which the customer was focusing on a holistic solution.

To address these topics of interest, the facility management team worked with their water treater partner to implement a solid-form water treatment system in place for their five cooling tower and chillers, each with 1,000 tons of refrigeration, with slightly soft municipal water for make-up.

Photo 1: Shopping Center comfort cooling equipment Photo 1: Shopping Center comfort cooling equipment

|

With the solids implementation, it was decided to increase the cycles of concentration from 5 to 10, which enabled significant water savings and reduced chemical usage. Additionally, PLC controllers were installed to allow for automatic, ongoing corrosion measurement without the need for corrosion coupons and automatic control of the number of operating chillers needed at any one time. The system uses “bleed and feed” methods to feed the water treatment chemistry.

Photo 2: Shopping center solid-form water treatment implementation. Photo 2: Shopping center solid-form water treatment implementation.

|

As shown in the following charts, the new solid chemical system provided as good or better system protection as the previous liquid chemical system.

Results of Corrosion Rate Testing:

|

Months of 2013

|

Liquid Water Treatment

|

Solid-form Water Treatment

|

|

Values Obtained

|

Rating

|

Values Obtained

|

Rating

|

|

April

|

1.9 mpy

|

* * * * *

|

|

|

|

May

|

2.2 mpy

|

* * * * *

|

|

|

|

June

|

2.0 mpy

|

* * * * *

|

|

|

|

July

|

|

|

2.1 mpy

|

* * * * *

|

|

August

|

|

|

1.8 mpy

|

* * * * *

|

|

September

|

|

|

2.2 mpy

|

* * * * *

|

|

Total Average

|

2.03 mpy

|

* * * * *

|

2.03 mpy

|

* * * * *

|

Results of Deposits Rate Testing:

|

Months of 2013

|

Liquid Water Treatment

|

Solid-form Water Treatment

|

|

Values Obtained

|

Rating

|

Values Obtained

|

Rating

|

|

April

|

27.2 mg/m2.d

|

* * * * *

|

|

|

|

May

|

28.1 mg/m2.d

|

* * * * *

|

|

|

|

June

|

26.5 mg/m2.d

|

* * * * *

|

|

|

|

July

|

|

|

32.6 mg/m2.d

|

* * * * *

|

|

August

|

|

|

33.8 mg/m2.d

|

* * * * *

|

|

September

|

|

|

39.6 mg/m2.d

|

* * * * *

|

|

Total Average

|

27.26 mg/m2.d

|

* * * * *

|

35.3 mg/m2.d

|

* * * * *

|

Chemistry of Water Expressed in Ryzner Index:

|

Months of 2013

|

Liquid Water Treatment

|

Solid-form Water Treatment

|

|

Values Obtained

|

Rating

|

Values Obtained

|

Rating

|

|

April

|

6.2

|

* * * * *

|

|

|

|

May

|

6.3

|

* * * * *

|

|

|

|

June

|

6.4

|

* * * * *

|

|

|

|

July

|

|

|

5.4

|

* * * * *

|

|

August

|

|

|

5.3

|

* * * * *

|

|

September

|

|

|

5.2

|

* * * * *

|

|

Total Average

|

6.3

|

* * * * *

|

5.3

|

* * * * *

|

Results of Microbiological Control (Dip Slide Analysis):

|

Months of 2013

|

Liquid Water Treatment

|

Solid-form Water Treatment

|

|

Values Obtained

|

Rating

|

Values Obtained

|

Rating

|

|

April

|

0.8 x 10-3 CFU

|

* * * * *

|

|

|

|

May

|

0.9 x 10-3 CFU

|

* * * * *

|

|

|

|

June

|

0.7 x 10-3 CFU

|

* * * * *

|

|

|

|

July

|

|

|

1.6 x 10-3 CFU

|

* * * * *

|

|

August

|

|

|

1.8 x 10-3 CFU

|

* * * * *

|

|

September

|

|

|

1.8 x 10-3 CFU

|

* * * * *

|

|

Total Average

|

0.8 x 10-3 CFU

|

* * * * *

|

1.7 x 10-3 CFU

|

* * * * *

|

Results of the Evaluation of the Cycles of Concentration:

|

Months of 2013

|

Liquid Water Treatment

|

Solid-form Water Treatment

|

|

Values Obtained

|

Rating

|

Values Obtained

|

Rating

|

|

April

|

5.3 / 5.25

|

* * * *

|

|

|

|

May

|

5.4 / 5.26

|

* * * *

|

|

|

|

June

|

5.5 / 5.44

|

* * * *

|

|

|

|

July

|

|

|

9.0 / 9.15

|

* * * * *

|

|

August

|

|

|

8.9 / 8.99

|

* * * * *

|

|

September

|

|

|

9.5 / 9.62

|

* * * * *

|

|

Total Average

|

5.4 / 5.31

|

* * * *

|

9.1 / 9.25

|

* * * * *

|

In addition to maintaining effective system protection, the solid-form water treatment system helped address many of the environmental concerns of importance to the shopping center management team:

|

Performance Ratios

|

Liquid Program

|

Solid Program

|

|

1 – Control of Corrosion

|

* * * * *

|

* * * * *

|

|

2 – Control of Deposits

|

* * * * *

|

* * * * *

|

|

3 – Control of Fouling

|

* * * * *

|

* * * * *

|

|

4 – Microbiological Control

|

* * * * *

|

* * * * *

|

|

5 – Net Loss of Water

|

* * * *

|

* * * * *

|

|

6 – Rate and Cycles of Concentration

|

* * * *

|

* * * * *

|

|

7 – Analytical Results of Corrosion Preventive Agents

|

* * * * *

|

* * * * *

|

|

8 – Consumption of Chemicals

|

* * * *

|

* * * * *

|

|

9 – Dosing Systems

|

* * *

|

* * * * *

|

|

10 – Control Systems and Monitoring

|

* * *

|

* * * * *

|

|

11 – Storage Space for Chemical Containers

|

* *

|

* * * * *

|

|

12 – Storage Space for Empty Containers

|

* *

|

* * * * *

|

|

13 – Need to Build Containment Basins

|

* *

|

* * * * *

|

|

14 – Occupational Safety

|

* * *

|

* * * * *

|

|

15 – Operating Facilities

|

* * *

|

* * * * *

|

|

16 – Environment

|

* *

|

* * * * *

|

|

17 – Heat Exchange Efficiency

|

* * * * *

|

* * * * *

|

|

18 – Specific Energy Consumption

|

* * * * *

|

* * * * *

|

|

19 – Cost of Water Treatment

|

* * * * *

|

* * * *

|

|

20 – Return on Investment

|

* * * *

|

* * * *

|

|

Total Average

|

* * *

|

* * * * *

|

Governmental Office Building

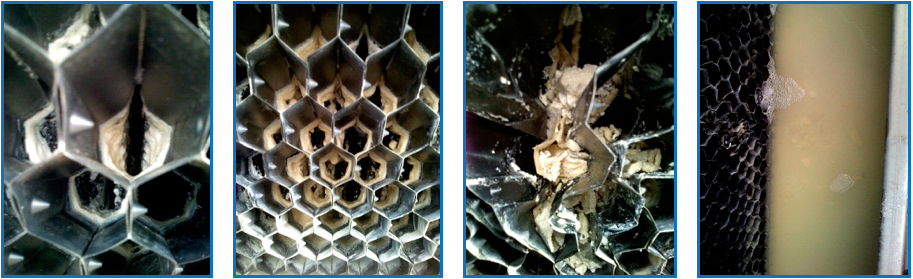

In mid-2007, the facility management team at this Federal Building had just replaced two 800-ton chillers and one 300-ton chiller with two new 900-ton chillers and a 400-ton chiller. They also replaced the cooling towers with new stainless steel Marley cooling towers. After only six months of operation, the cooling tower fill had accumulated 1/4" of scale in some areas.

So much scale had built-up inside the fill that it began to crumble and stack up at the bottom near the basin due to the weight (see Photo below). The basin of the tower, below the water line, and the cooling tower hot distribution decks were also very scaled.

The building’s facility management team decided to transition their water treatment to a solid water treatment chemicals solution in December 2007.

Photo 1-4 of government office building cooling tower showing scaling issues. Photo 1-4 of government office building cooling tower showing scaling issues.

|

The contracted water treater began treating the building systems in January, 2008 using the Stick form of a solid online cleaner product initially and over time, switched to a solid-form online cleaner in gallon bottles from a dissolver/feeder unit.

Positive results were visible almost immediately. Within a couple of months, the scale inside the fill was markedly thinner. After approximately 5 months, the scale that had formed on the cooling tower basin had also started to become thin and began flaking from the basin. After a little over one year, the cooling tower fill was almost completely clean and the basin scale had gone from 1/4" in thickness to eggshell-thin and was flaking away.

Photo 5-7 of government office building cooling tower showing no scale after treatment with solid water treatment products. Photo 5-7 of government office building cooling tower showing no scale after treatment with solid water treatment products.

|

The chillers were opened for annual inspection and routine maintenance in 2008. Although it was evident that the scale deposits were being removed, the two 900-ton chillers did still contain scale. These two chillers alternate, so they are not always running. The 400-ton chiller is the most active. It is loaded almost constantly and is even used as the after-hours chiller. When opened for maintenance, it was completely clean of all scale. By it running more than the other two chillers the solid-form online cleaner water treatment was able to clean it up most optimally.

The building facility management team was extremely impressed with these results. The solid-form water treatment distributor has since been awarded 14 additional buildings due largely in part to the success cleaning up this building’s Towers and Chillers.

Summary

When introduced about 15 years ago, solid water treatment chemicals were viewed by many water treaters as a product that simply would not work to treat cooling water systems. Now, with thousands of successful installations worldwide in cooling towers (as well as boilers and closed loop systems), solid-form water treatment solutions are considered to be the legitimate future of water treatment and exists in hundreds of water treaters’ “tool belts”.

These water treatment professionals understand that if applied correctly, solid-form products can be just as effective of a method to protect cooling and heating systems from corrosion and scale as their liquid counterparts. And with the additional sustainability, safety, ease of use, and shipping cost benefits of solids, hundreds of facilities are transitioning to these products each year world-wide.

Source: coolingbestpractices.com