For two years running, the Mercedes Formula 1 team and its star driver Lewis Hamilton have reigned supreme over their hypercompetitive sport. Tight new regulations on car technology and engines were supposed to make Formula 1 a more egalitarian competition, but Mercedes has defied those expectations and delivered two seasons of outright dominance. The only real threat to Hamilton’s hegemony in this time has been his own teammate, Nico Rosberg, which is testament to the substantial technical lead that both drivers have enjoyed.

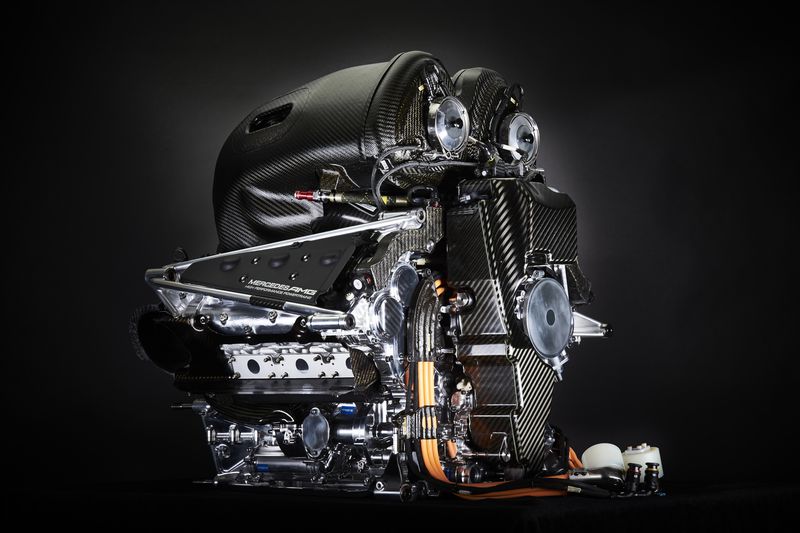

This month, Mercedes opened the doors to its Brixworth facility in rural England to tell the story of how its world-beating Formula 1 hybrid power unit is designed and built, and I was there for a first-hand look. It’s called a power unit now because the engine is just one component of it — there’s a fantastic amount of extra work and technology that goes into the Mercedes cars’ electric power subsystem. Taken as a whole, this is the most advanced and, on the evidence of F1 results, best high-performance locomotion system that’s yet been devised. And it’s all achieved by prioritizing the same thing as road-going car engineers do: efficiency.

The British countryside seems like an unusual setting for cutting-edge German engineering, and indeed most of the work and development at Brixworth is done by British engineers. Before it became known as Mercedes AMG High Performance Powertrains, the company operating in this Northamptonshire location was called Ilmor Engineering. Founded by Mario Illien and Paul Morgan in the early ‘80s, it began by developing IndyCar engines and later partnered with Mercedes-Benz on Formula 1 engines, which eventually led to the takeover of its UK operations by the German carmaker. This is why Mercedes’ most advanced development is happening outside of Germany, and also how an F1 team with a short history of operating under its own name is able to outpace the established titans of the sport. Some of the people working at Brixworth have been there for 25 years or more.

"FORMULA 1 AND ROAD CAR DESIGN MISSIONS ARE ALIGNING AROUND EFFICIENCY."

Andy Cowell, one of the Mercedes-Ilmor veterans, is the new company’s managing director, having previously served as a leading engineer at Cosworth Racing and BMW Motorsport. He gave us a tour of Mercedes’ hybrid PU and the surrounding manufacturing plant. "Formula 1 and road car design missions are aligning around efficiency and engine downsizing," says Cowell. To illustrate the point, he notes that the original 2012 design — from which the championship-winning 2014 and 2015 PUs sprouted — weighed a hefty 262kg, too much to even fit into an F1 car. Mercedes’ first Kinetic Energy Recovery System (KERS, which puts motors at the wheels that gather energy when the car decelerates) also weighed 107kg at its outset in 2007. Since then, the KERS efficiency has gone from 39 percent to 95 percent and its weight has been reduced to less than 20kg. The whole power unit has gotten smaller, hitting the mandatory minimum of 145kg, and significantly more efficient: 2015’s GE model was the most powerful in Mercedes-Benz’s history, in spite of having to adhere to new FIA regulations that state it can’t be fed fuel at a rate of more than 100kg per hour.

Thermal efficiency is the paramount concern at Mercedes. That’s the measure of how much of the heat produced by the engine is converted into meaningful power for the car, and the company says its latest PU surpasses 45 percent. Having been at 29 percent in 2013, Mercedes has made a bigger advancement in the past few years than in the previous century and change — following the first internal combustion engines, which had a 17 percent thermal efficiency in the 1870s. In practical use, Mercedes can notch the efficiency up beyond 50 percent with the help of regenerative braking, via KERS, and energy harvesting from the exhaust using a special turbine. Exhaust heat hits that turbine at 1,000 degrees Celsius before exiting at 600 degrees. The collected energy is sent into a densely packed, liquid-cooled lithium-ion battery, which is used to add a supplemental 161hp to the rear wheels and power the car’s electric turbo.

F1 ENGINEERS HAVE QUICKLY BECOME EXPERT AT RECYCLING HEAT AND KINETIC ENERGY

The electric component of the power unit is critical, according to Cowell. He joins a wide consensus in the motorsport industry in believing that the internal combustion engine working by itself is a dinosaur set for extinction. Hybrid systems are simply more efficient. That being said, a significant consideration in Mercedes’ power unit design was ensuring that the engine retained the characteristic F1 high-pitched whine. Cowell might have preferred dropping the revs even lower than 15,000, but Formula 1 is as much an entertainment as it is a sport, and its fans and participants insist on maintaining some of its traditions. Having listened to one of Mercedes’ engines being tested at full throttle in the factory, I can confirm that it does indeed retain the signature sound known and loved around the world.

In order to make its efficiency advancements, Mercedes constantly iterates on its designs through a mix of simulation and experimentation. Many of the finer details can be computed using sophisticated software, such as moving-mesh computational fluid dynamics, which allows the company to precisely model charge and combustion processes inside the engine, allowing it to assess the effects of varying fuel characteristics (such as evaporation or combustion rates). But that simulation only goes so far, and many of the company’s theories are proven out by real-world testing. "Yes, you need to have good ideas. But you need to go round that loop many, many times," says Cowell.

A MANUFACTURING PLANT WORKING 24/7 TO PRODUCE JUST EIGHT ENGINES PER YEAR

The Brixworth plant is active and working 24 hours a day, with night-shift workers keeping it going through the small hours. Though some of the bigger components are shipped in from Germany, things like the energy-harvesting turbine, which is hewn out of a special alloy designed by Mercedes itself, are made on the Mercedes premises in the UK. "We are an R&D company," explains Cowell, as he walks us through the floor where the company’s engineers and metallurgists develop their ideas. There’s nothing special about the equipment — it’s just a bunch of Dell monitors, Logitech mice, and a few microscopes — but it’s the closeness of this research arm to the manufacturing plant that allows the company to move fast. Every new idea can be immediately put to the test and either improved upon or discarded.

Every season, the Mercedes F1 team is allowed to use only four PUs per driver before incurring a penalty. That means that all this constant labor — iteration, testing, refinement, reiteration, more testing — is in the service of producing just eight engines and battery packs a year. Brixworth looks and works like an engine factory, with the only difference being that most of the stuff it builds and manufactures never sees the light of day. It almost feels futile.

"It’s like panning for gold," is how Cowell describes his team’s research and development work. "Most days you only get small crumbs" of efficiency improvements, "but one day you land on a big nugget." Those advances, little and small, do add up, and not just for Mercedes, which improved its fuel efficiency by 37 percent between 2013 and 2014. The typical Formula 1 car used to consume around 150kg of fuel per race two years ago, but today it’s bound by a hard limit of 100kg.

ENVISIONING A FUTURE OF TRICKLE-DOWN ENGINEERING

Mercedes maintains tight secrecy around its engineering processes — to the point where I had to have my phone’s cameras taped up — but the formula for the company’s success is no secret. The German carmaker has developed, in its own words, a "high performance development loop across road and track focused on conversion efficiency and waste energy recovery." Doing more with less, in other words. Having taken over an already successful engine maker, Mercedes brought its own engineering knowhow and vast resources to bear — it built out the production facilities at Brixworth — and it’s now reaping the fruit of its investment.

Looking to the future, Mercedes sees increasing relevance of its F1 development to road-going cars. Cowell cites ABS brakes, traction control, carbon fiber structures, and tire pressure sensors as examples of current road car technologies that were first developed on the track. With his belief that sports and road car power systems are converging, it’s only logical that more of what we see on racing Sundays will trickle its way down into what we can drive on weekdays.

Source: theverge.com