Vives College University and Kulab (KU Leuven University campus Ostend) in Belgium are undertaking an aeronautical research program for the development of a new UAV aimed at performing scientific missions along the Belgian coastline above the North Sea. The main performance requirement of the UAV, dubbed Litus, is to be electrically powered with a range of 160 km and a payload up to 5 kg.

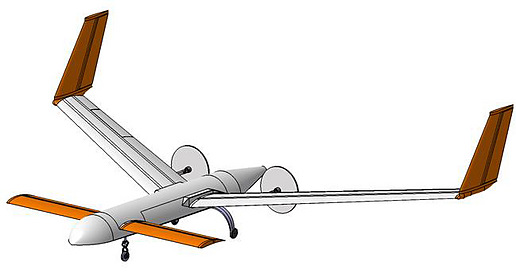

The Vives Litus UAV features a canard configuration with swept wings and a vertical tail at each wing tip.

The Vives Litus UAV features a canard configuration with swept wings and a vertical tail at each wing tip.

During the conceptual design stage, several different aircraft configurations were investigated. This ranged from a conventional configuration to a twin-boom configuration. Eventually, a canard configuration with swept wings and a vertical tail at each wing tip was chosen for its aerodynamic efficiency. The final design resulted in a UAV that has an overall span of 5.87 m and a length of 3.43 m and which can cruise at 80 km/h for 2 h with a payload of 5 kg, meeting the requirement of a 160 km range. The maximum take-off weight will be 65 kg. A propulsion system of two electrical brushless dc motors was selected to minimize the environmental impact during operations by avoiding gas emissions and reducing noise emissions. A push-configuration with two independent propulsion systems was selected to comply with safety requirements.

During the design phase of the project, simulation models of the electrical network were created with the multiphysics simulation software LMS Imagine.Lab AMESim. First, the electrical system that will be used during the test flights was completely modeled.

Also the input control signals were modeled and are used to control the behavior of the electrical system. The objective of the electrical system model was to support the sizing of the components and batteries to achieve the required performance. Therefore, the modeling of the components focused on their energetic and thermal behavior and not on their dynamic behavior. The energetic behavior of all components was validated on test benches.

Afterward, the electrical system model was also extended with thermal behavior of all components inside the fuselage to identify if additional ventilation of the fuselage is needed or dedicated cooling of some components. The outcome of these simulations was that cooling was needed for the ESC.

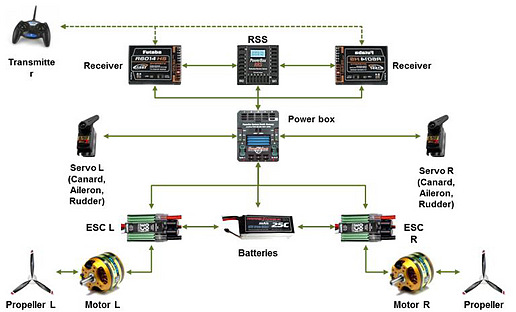

This diagram shows the architecture of Litus’ main electrical circuits (control, motor left and right).

This diagram shows the architecture of Litus’ main electrical circuits (control, motor left and right).

The real-time simulation of complex systems has become recently possible due to technological breakthroughs and recent advances in computation power and multi-core processor architectures. In this case, recent improvement in the efficiency of the LMS Imagine.Lab AMESim solver has enabled the use of dynamic simulation models of relatively complex systems in real time. As a result, software-in-the-loop, hardware-in-the-loop (HIL), and pilot-in-the-loop (PIL) applications can now make direct use of physics-based simulation models that are created during the design phase of the system. This removes the need to create new approximation models. Moreover, the key physical parameters can still be changed for real-time applications.

In this case, the pilot-in-the-loop simulator ran on a standard workstation, with higher performance possible on a dedicated real-time platform.

In this case, the pilot-in-the-loop simulator ran on a standard workstation, with higher performance possible on a dedicated real-time platform.

In the case of the electrical network model of the Litus, all component elements used already are in form of a quasi-static description, except for the batteries. This means that the models did not include fast transient effects as this was not required for the energy management and thermal management analyses for which it was used. On the contrary, the model of the servo motors was extended to capture better their performance limits.

In the original simulation model, a servo motor was modeled as a variable resistance where a look-up table contained the measured relationship between the servo rotation angle and the power consumption. There was also a look-up table to define the relation between the user input and the servo force which was not used.

In the real-time model, the model of the servos was replaced with a model that also takes into account the maximum rotation speed of the servo. Additionally, the aerodynamic force is also taken into account based on an analytical formulation for hinge models of control surfaces.

The behavior of the servo motor was validated with a step input in an isolated model. The results showed that initially the maximum rotation speed is used and subsequently the servo angle converges to an angle near the required angle.

The flight simulator of the Litus takes into account the electrical system. Therefore, the real-time model of the electrical system will be used in a PIL simulation, essentially a flight simulator.

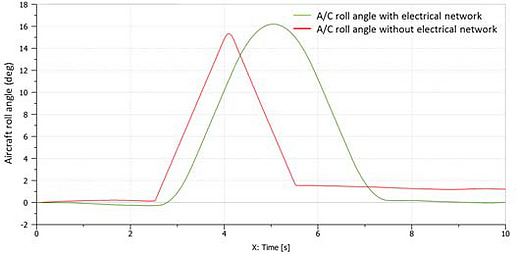

This graph compares the resulting roll angle and roll angle of the same maneuver but where the user input is sent directly to the flight dynamic module, hence without servo properties. This latter plot illustrates the effect of the electrical system model on the flight dynamics of the aircraft.

This graph compares the resulting roll angle and roll angle of the same maneuver but where the user input is sent directly to the flight dynamic module, hence without servo properties. This latter plot illustrates the effect of the electrical system model on the flight dynamics of the aircraft.

A mission profile composed of five phases was flown with the flight simulation. First is the take-off phase during which the throttle is set to maximum (100%). This phase takes about 10 s. Subsequently, there is the climb phase where the throttle is set to 90% and the elevator settings are increased. The climb phase is performed for about 100 s. The next phase is the cruise phase where the thrust is set to 75% and the elevator settings are reduced. This is maintained for about 400 s. Finally, there are the descent and landing phases where the thrust of the engines is further reduced.

The electrical network model of the Litus UAV that was created during the development phase has been successfully used as a real-time capable simulation model without major changes. This simulation model has been coupled with flight dynamics and visualization modules of the open source simulation software FlightGear. It was demonstrated that during the PIL simulation key parameters of the electrical network can be visualized. Moreover the effect of the performance of the key electrical components, such as servo motors, on the flight dynamics can be taken into account during real-time simulation. Consequently, this research confirms that the proposed simulation architecture is suitable to take into account the effect of the electrical system on the aircraft flight dynamics.

Source: sae.org