Our engineers and designers have been hard at work, striving to realize our vision for the future of transportation. Their efforts take a variety of shapes – from the resilient lines that comprise the adaptable framework of our Variable Platform Architecture, to the dramatic silhouette of the FFZERO1 Concept, to even one that may appear a touch more modest…

…such as a small box, for instance.

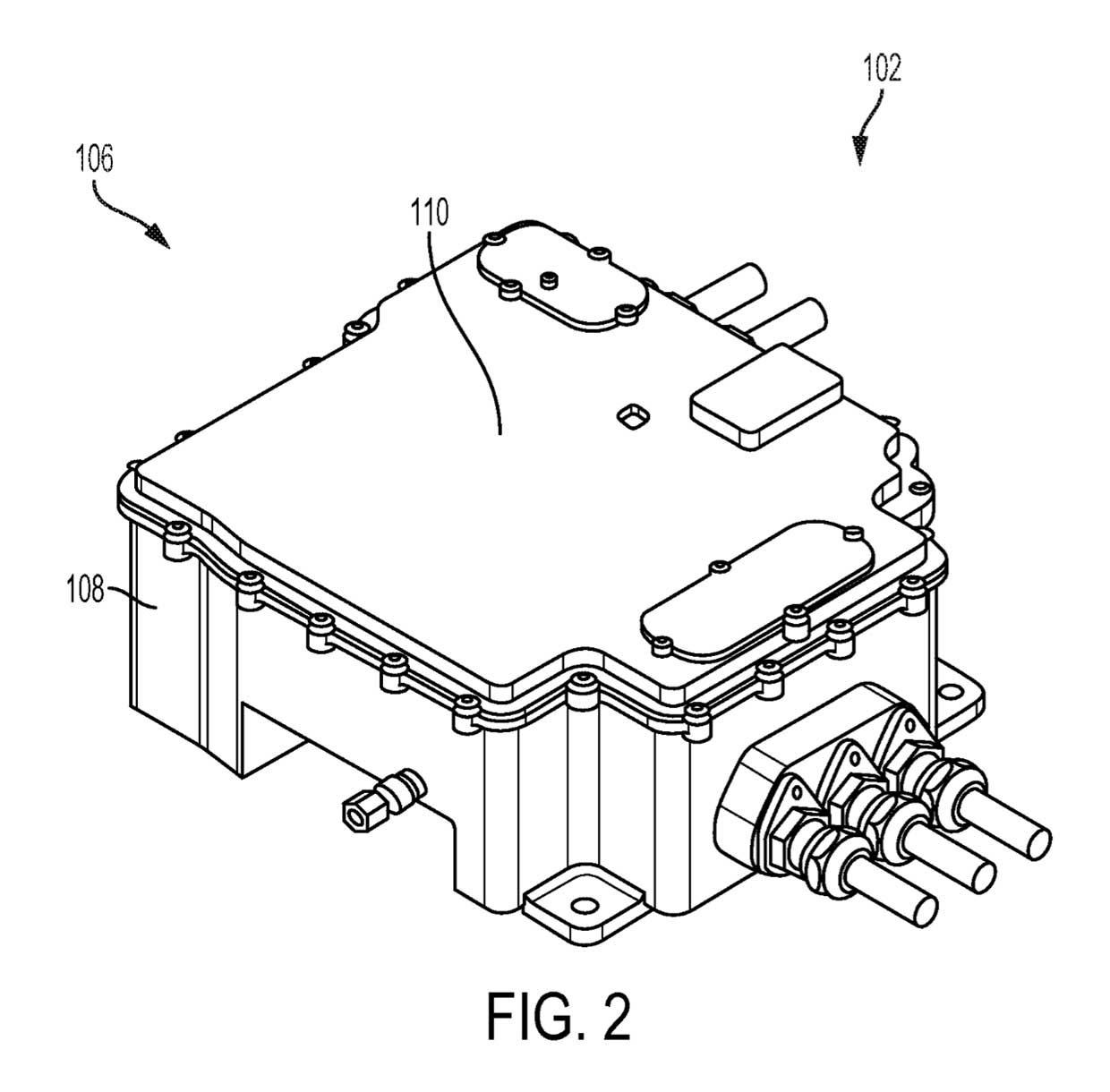

We are proud to announce that we have earned our very first U.S. patent (#9,241,428 B1) for a cutting-edge power inverter that we call the “FF Echelon Inverter.”

Our team of engineers, led by Silva Hiti, Senior Director of Electric Drive at FF, sat down to solve several long-standing challenges facing current production inverters. Issues with reliability, manufacturability, and power density were key obstacles they wished to overcome when designing this new device from the ground up.

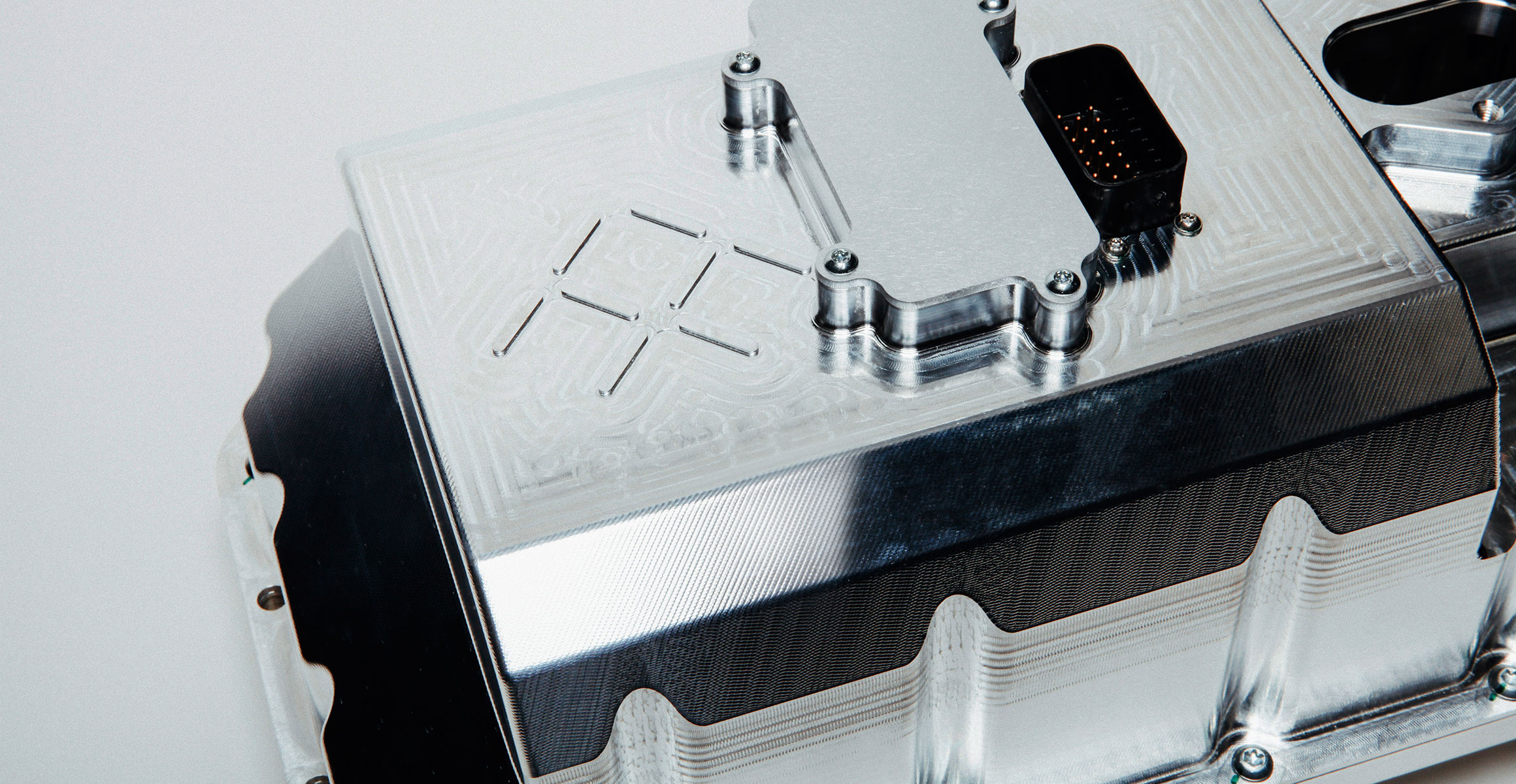

First and foremost, our engineers sought to reduce the mechanical complexity of our inverter while meeting the ambitious performance requirements we aimed to achieve.

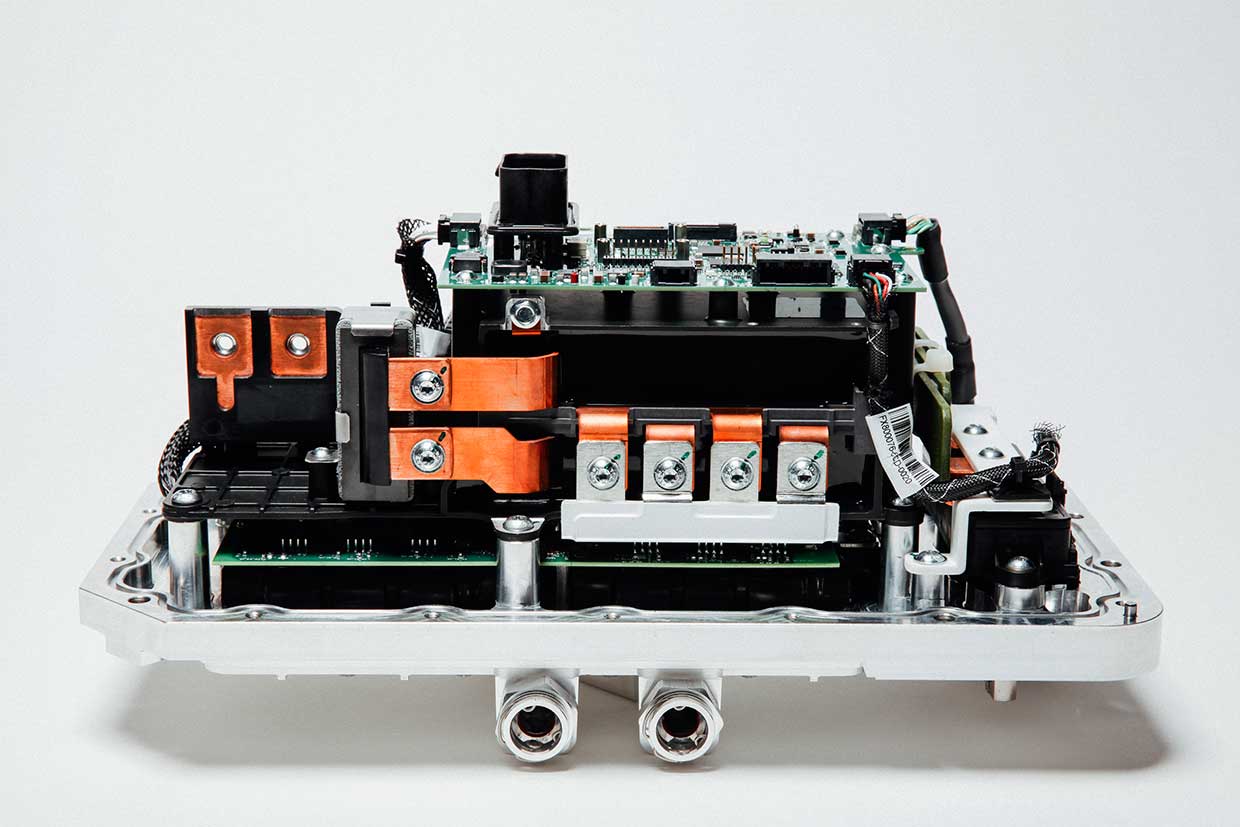

Our engineers decided to reduce the inverter to its essential elements. Instead of trying to put together a functioning inverter from off-the-shelf parts, they instead pursued an entirely original inverter architecture – one that offered a simpler, more straightforward design.

“Condensing the number of transistors and other complex components enhances the inverter’s overall stability and dependability,” explained Silva Hiti, “allowing us to accomplish far more, with fewer materials.”

An ageless engineering mantra states that the more interacting parts you integrate into a system, the more opportunities you have for something to go wrong. With power inverters, such issues could include an asymmetrical sharing of current across parallel components, causing certain parts to experience unforeseen stress. Eventually, this stress could lead the inverter to shut down – possibly causing your car to suddenly stop moving altogether.

Concentrating the FF Echelon Inverter’s design to its core elements makes it far easier to monitor and ensure against these intricate issues – resulting in a safer, more dependable machine.

Additionally, this will result in decreased manufacturing expenses, since the testing necessary to safeguard against these concerns is much less cost-intensive when analyzing such a reduced number of components. Its production will be less demanding, as well – both in the complexity of the process and its environmental impact. Its overall package will also be more compact, allowing for expanded interior cabin space and a more comfortable passenger experience.

The FF Echelon Inverter’s unique design supports an unprecedented degree of what’s known as power density – meaning that it can transform energy more efficiently, while encompassing less space.

When driving our electric motor, the FF Echelon Inverter achieves 20-30% greater power density than our competitors’ applications, allowing it to transform that many more watts for every gram of its weight.

The FF Echelon Inverter was conscientiously engineered to manage power levels well beyond the known limits of electric vehicles today, and offer industry-leading performance in the years to come.

We are extremely proud of this first patent for the FF Echelon Inverter. Not only is this a remarkably powerful, future-proof piece of technology on its own, but it also offers a look into the broader landscape of engineering innovations that we are currently developing at FF. In fact, over the last year we have submitted over 100 new patents to the U.S. patent office.

Performance, reliability, safety, and simplification are pervasive in FF’s design ideology. From expressive aerodynamic exteriors to thoughtfully improved interior components, our talented engineers and designers are embracing this vision and pursuing exciting new approaches to remedy long-standing issues in the industry.

Such inventive methods can lead to more powerful technology, more environmentally responsible production, and enhanced safety and reliability.

Ingenuity can take many shapes. Sometimes even ones as seemingly simple as a small box.

Source: Future Faraday